VESKO-S

2 – 6 MW

Fuel – straw (cereals, hay) in bales.

This boiler is designed for heat producers in municipal boiler plants and in industry.

Straw is a very promising fuel with regard to the use of renewable energy sources. Slovak agriculture produces large amounts of straw which is unused due to the decline in livestock farming. Thanks to this, there is space for its utilisation for energy purposes.

Another advantage of straw is sufficient processing capacity. Agricultural companies dispose of a sufficient number of machinery for the collection, pressing and transportation of straw. Hence, the use of straw as fuel does not require new investment in this type of processing equipment.

Straw is a quality fuel. It is collected and processed when dry. Thanks to baling it reaches a big specific weight, which reduces transportation and storage costs.

The potential of the use of straw is high. It is, however, necessary to choose the right technology. Some straw combustion equipment requires straw chopping (or crumbling) to smaller fractions. This increases its costs because it is first necessary to spend energy in straw pressing and then in straw crushing. This, moreover, disproportionately increases the noise and dust levels of such processing.

It is therefore more suitable to combust straw in entire bales. This simplifies its handling, and reduces noise and dust. VESKO-S boilers are designed precisely for the use of straw bales for energy purposes.

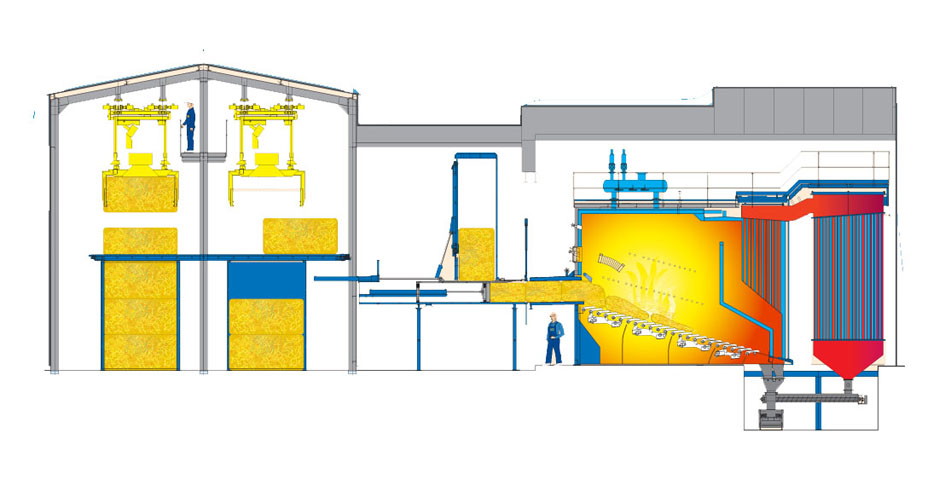

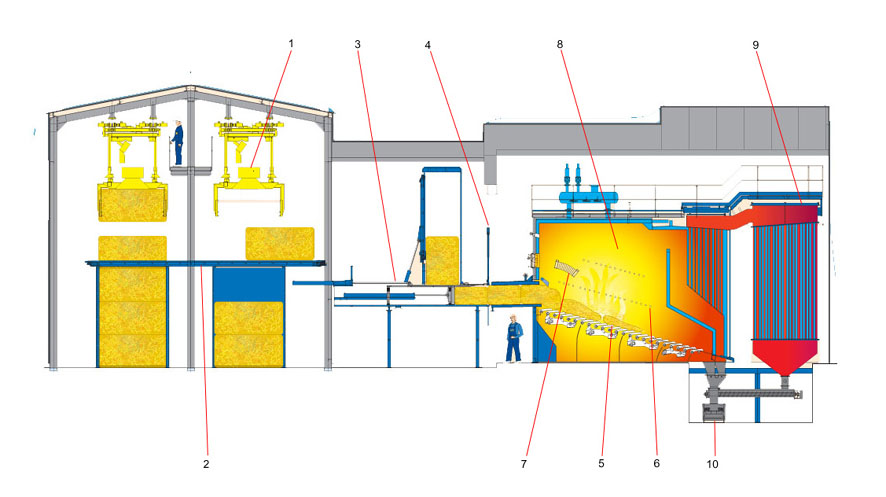

Description of the VESKO-S boiler

The VESKO-S boiler has a self-supporting, entirely welded box construction. The lower part of the boiler is made up of a furnace chamber with an inclined sliding grate. The grate is controlled by means of a hydraulic mechanism, and is cooled by combustion air. The combustion chamber is cooled by water.

The exhaust gases first pass through the first duct of a conventional exchanger and then enter a twin-duct separated water exchanger. The exhaust gases are sucked from the boiler through the exhaust gas treatment system to the chimney.

1. Stacker

2. Straw transporter

3. Cutting mechanism

4. Gate

5. Inclined sliding grate

6. Combustion air inlet

7. Combustion vault

8. Combustion chamber

9. Separated exchanger

10. Ash conveyor

Function of the VESKO-S boiler

VESKO-S boilers are designed for central heating plants and industrial boiler plants. This concept allows the manufacturing of boilers with optimum parameters according to the specific requirements of the hot water network within the following range:

- Thermal output: 2,0 – 6,0 MW

- Operating over-pressure: 0,4 – 1,0 MPa

- Operating temperature: 90–110°C

Fuel

VESKO-S boilers combust angular bales of pressed straw.

The bales of straw are stored in stacks under the stacker. The automatic stacker picks up the straw bales and places them on the conveyor. The bales move towards the cutting mechanism and then to the vertical chamber where they are separated by a knife (in approx. three parts) and pressed by a piston to the boiler grate through a cooled tunnel. In order to prevent reverse burning, upon the back motion of the piston the fuel path is blocked by a water-cooled gate.

Benefits of the VESKO-S boiler design

- Perfect boiler automation

The boiler runs in an automatic mode. The combustion has been optimised on the basis of a vacuum in the combustion chamber and according to excess oxygen in the combustion products. The fuel feed and the movement on the grate are regulated according to the fuel characteristics.

All measured parameters, interventions of the safety equipment and defects are transmitted to the dispatching system.

- Use of entire straw bales

The delivery of straw bales is fully adjusted to the combustion of entire pressed straw bales, without any fragmentation or crushing and the need to remove binding. The handling of the fuel is automatic and free of noise and dust.