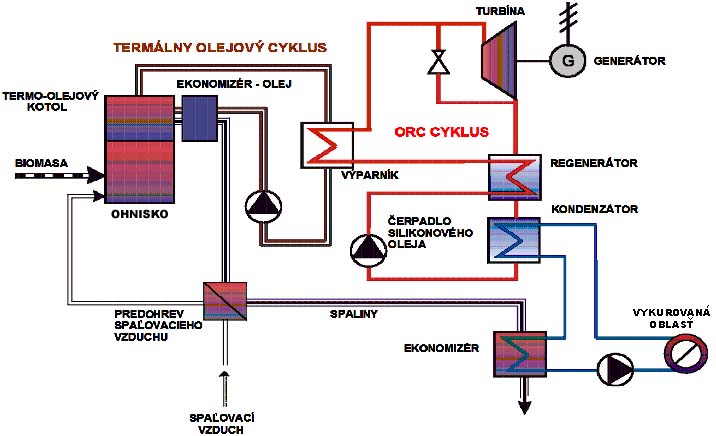

An important benefit of the ORC is the possibility to use biomass as a fuel for combined power and heat generation. Boilers for biomass combustion can be the source of heat in this case.

- Parameters of the equipment for the use of biomass

Input temperature of the thermal oil: 230 – 300°C

Working over-pressure of the thermal oil: max. 3 bar

Power output: 50 – 1,500kW

Low-potential heat acquired from a geothermal drill can also be used.

- Parameters of the equipment for the use of biomass

Input temperature of geo-thermal energy: 50 – 150°C

Power output: max. 200kW

ORC benefits compared to the steam turbine

The system can use energy with relatively low temperatures.

High turbine efficiency, mainly when partially loaded.

The low revolutions of the turbine allow for directly driving the generator.

Negligible erosion of the turbine blades (no drops from the working medium).

Low mechanical stress of the turbine components due to the low peripheral speed.

The possibility of any power control of the equipment within its entire power range.

The entire cycle runs at a maximum temperature of 300°C and a pressure of up to 10 bars – longer life-cycle of the equipment.

The life-cycle of boiler pressure parts is twice as long – low pressure, temperature, and chemical properties of the oil.

Simple operation of the equipment – unattended operation.

Minimal requirements for construction and space.

No need for chemical treatment of the used media.

High working reliability and low operating costs.